HISTORY

- Leatherex was established in 2000 with the technical collaboration of ASICS Japan. Primarily, it was exclusively for Japan market.

- It was relocated to its own manufactory in 2003 at the present location. It was financed mainly from the director’s equity participation.

- Leatherex expanded in 2006 to double its capacity and take forward European orders.

- In 2012, a joint venture with BZ MODA, Italy started to make traditional, classical and handmade Italian shoes.

- It was upgraded with an in-house component-making facility with a linkage in 2008.

ACHIEVEMENTS

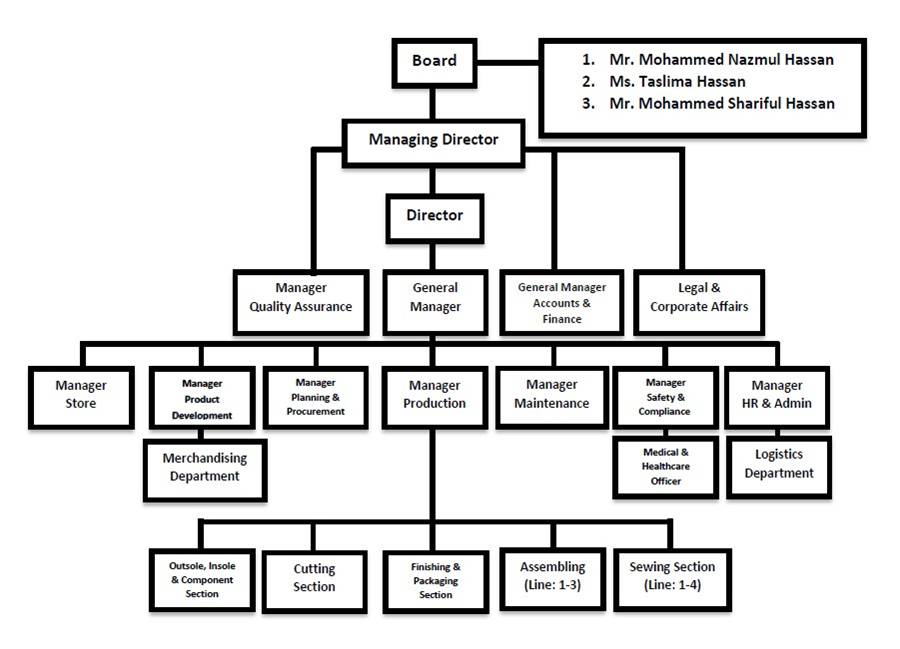

ORGANOGRAM

CAPACITY

Base Products: Leather Casual, Basic, Snickers, Moccasins, Dress Shoes, Mesh Shoes, Pumps, Men’s & Ladies Sandal, Boots, Kids Shoes.

Turnover (Yearly): 6 million US dollars approximately.

Yearly Capacity: 800,000 pairs (depends on design/article).

Building Area: 125,000 square feet.

Capacity Utilization in 2016: 50% (Free capacity to offer 50%).

Number of Employees: 1,050 employees.

Main Export Market: Japan, Korea, USA, Canada, Austria, Sweden, Germany Italy, UK, France, and Poland.

Machinery: “Torielli” – Italy, “Paff”- Germany, Olympic, “Nakamura”-Japan & Conveyor system- Taiwan.

Duty Free Raw Materials: The company has SUPERVISORY BOND LICENCE and import of all raw materials are duty-free covering GSP regulation.

Bank: The First Security Islami Bank Ltd., Dilkusha Branch, Dhaka; Dhaka Bank Ltd., Dhaka, Bangladesh.

OUR GROWING PARTNERS

CAPACITY

COMPLIANCES

- Leatherex Footwear Industries Ltd. is 100% compliant factory

- CSI, German Consultant has trained up LEATHEREX for compliance and introduced strict implementation of ethical trade manual ( ETI Base code).

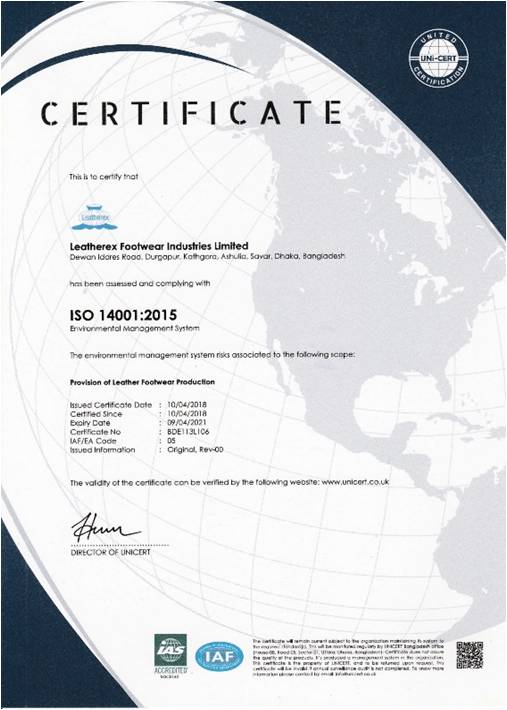

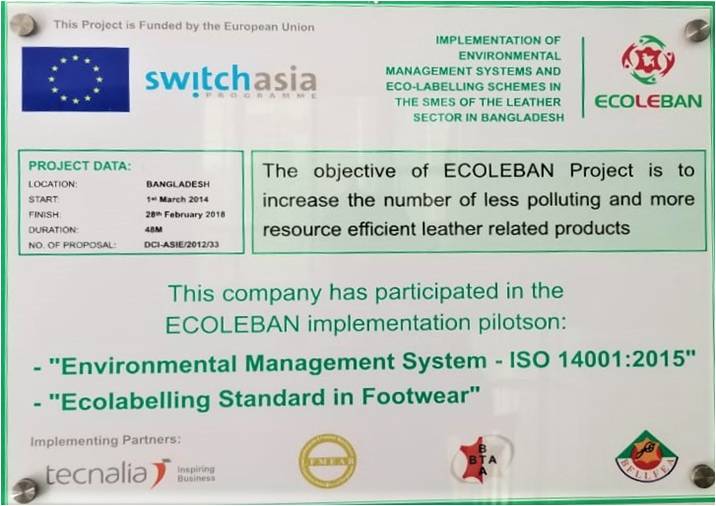

- We have achieved ISO-14001 2015 certificate certificate.

- We are working with ILO Better work since 2017. We have completed 3rd cycle very successfully and 4th cycle running.

- The factory has done COC & C-TPAT audit conducted by Omega compliance for CALERES.

- Omega compliance has given few findings and we have already resolved more than 80% findings.

- We are fully Amfori(BSCI) audited and audit conducted by reputed international audit firm Bureau Veritas.

- We are ensuring 100% safety and security of all employees, partners and products.

- We have WPC (Workers’ Participation Committee) which is elected as per labor law/ ILO Guideline.

ISO 14001:2015

CAPACITY

R & D, Sample development – PD & Service from CHINA office (ODM/OEM)

- We have designing and collection making facility in Italy and a sample development facility in China and in-house of Leatherex, Bangladesh.

- We develop and design outsole and design accessories through our own development office in China. We can open mold according to the

design, sample or CAD file. We work for ODM/OEM specifications. - Our China office is jointly working with Leatherex Dhaka team And Italian Designers closely according to the customer’s requirements.

- We can offer new collection for SS & AW every year.

Leatherex believes in growing with its customers. We feel proud knowing our customers are doing satisfied. We contribute to their success by becoming solid partners. Our business model is based on competitive pricing, high-quality manufacturing, and on-time shipment in the season. Our quality protection and guarantee are among the best in the industry. We have achieved Japanese quality standard success already. We currently have a 98.5% “product quality pass rate” during re-inspection in Japan, which is higher than any of our competitors from China and India.

We have several quality assurance options:

Option 1

Before packaging of our products, buyer inspects 100% with the support of the Quality Assurance Team of Leatherex.

Option 2

Buyer can nominate their representative to monitor and inspect the quality before shipment.

Option 3

Leatherex’s in-house QA (Quality Assurance) team checks and inspects 100% merchandise before shipment and a PSI certificate is issued to the buyer.

Replacement guarantee is given to the buyer for any problem caused by poor standard merchandising when the buyer receives a shipment.